|

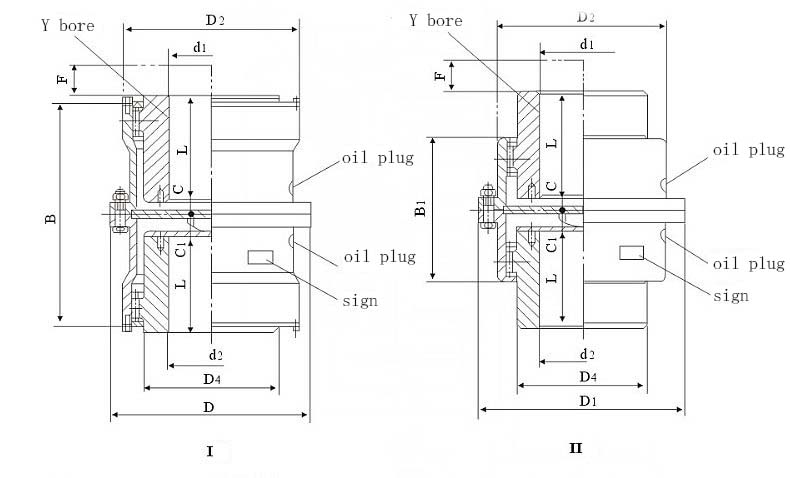

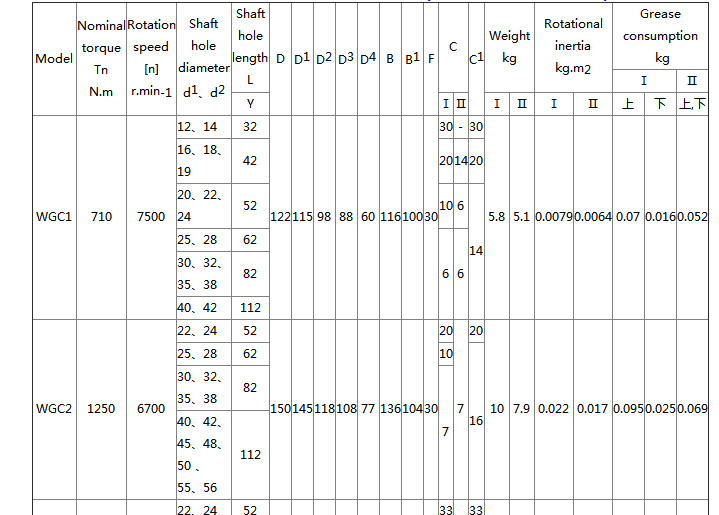

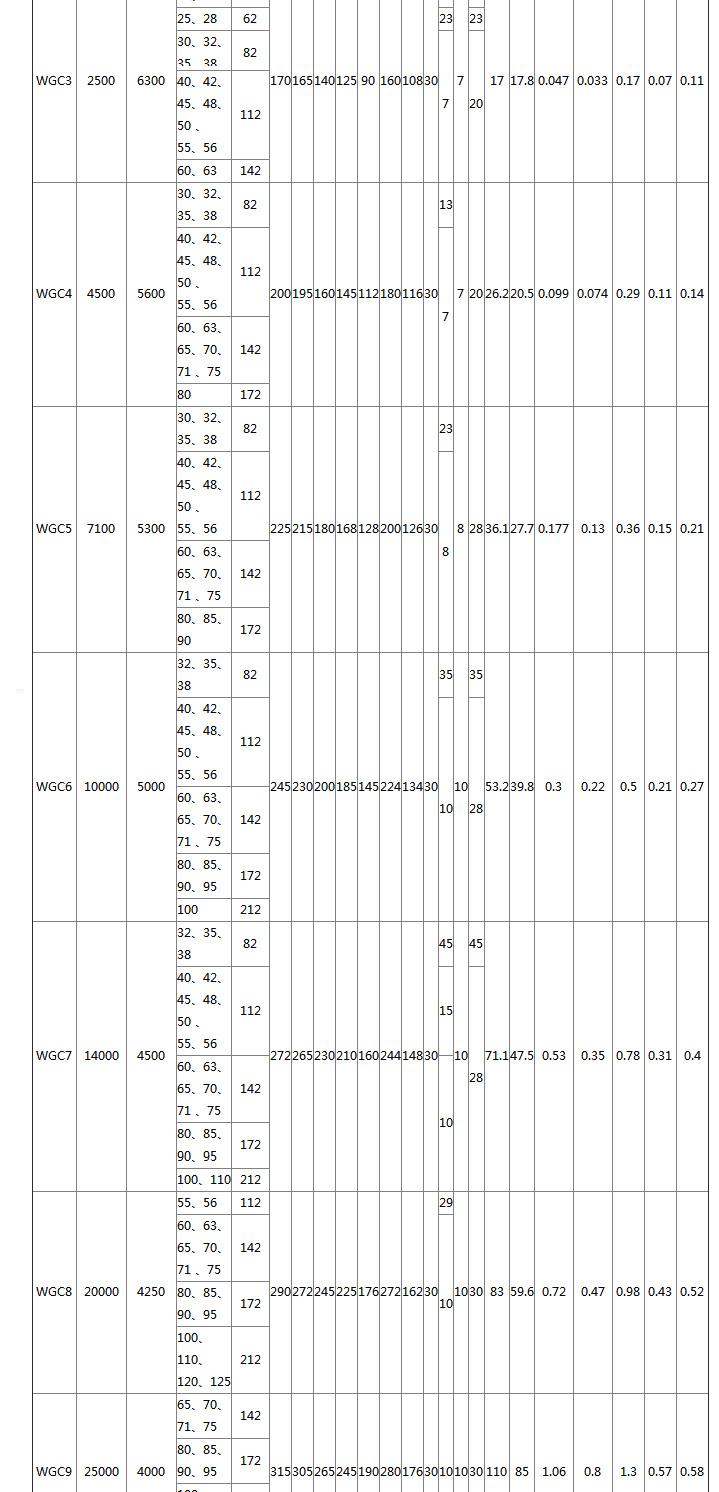

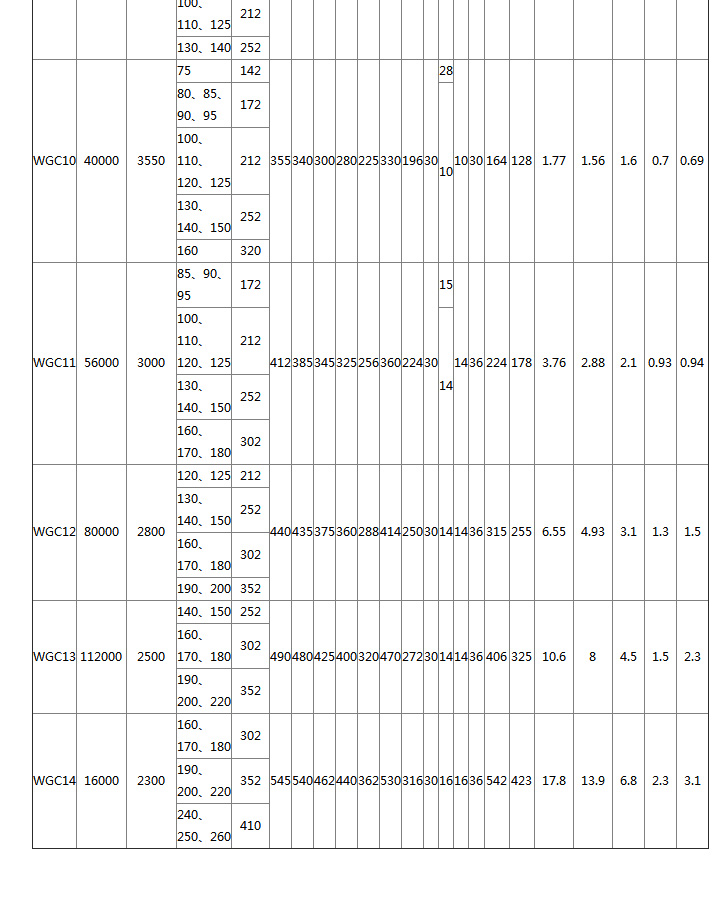

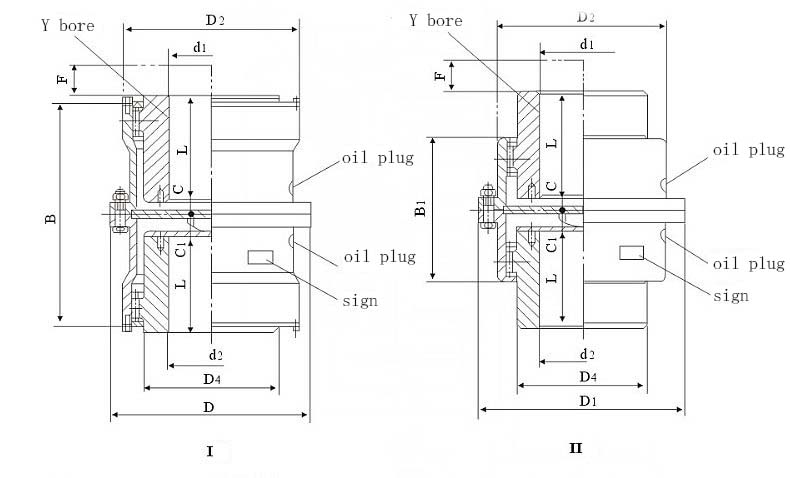

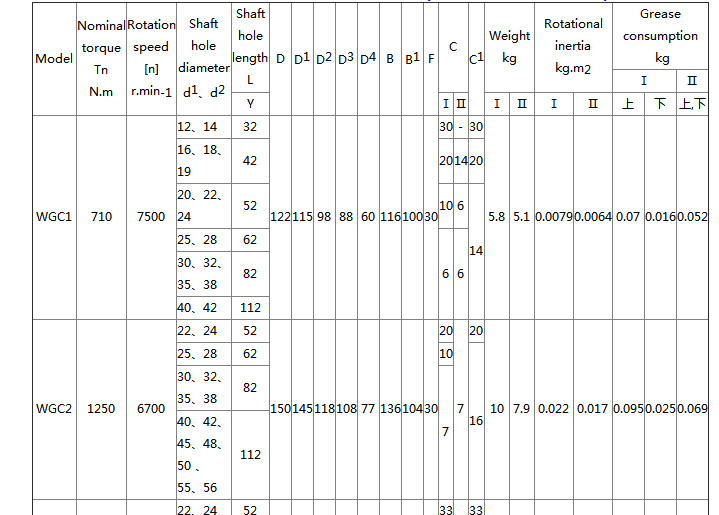

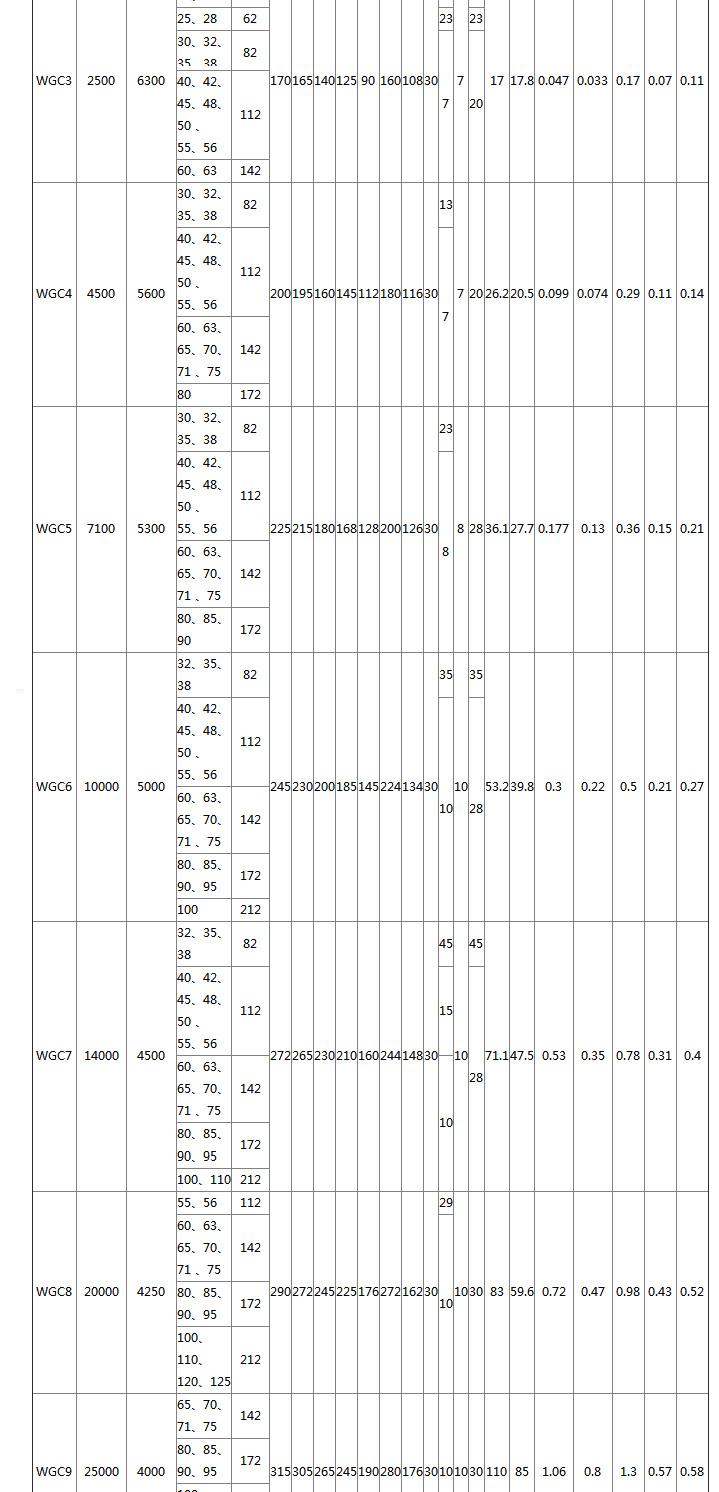

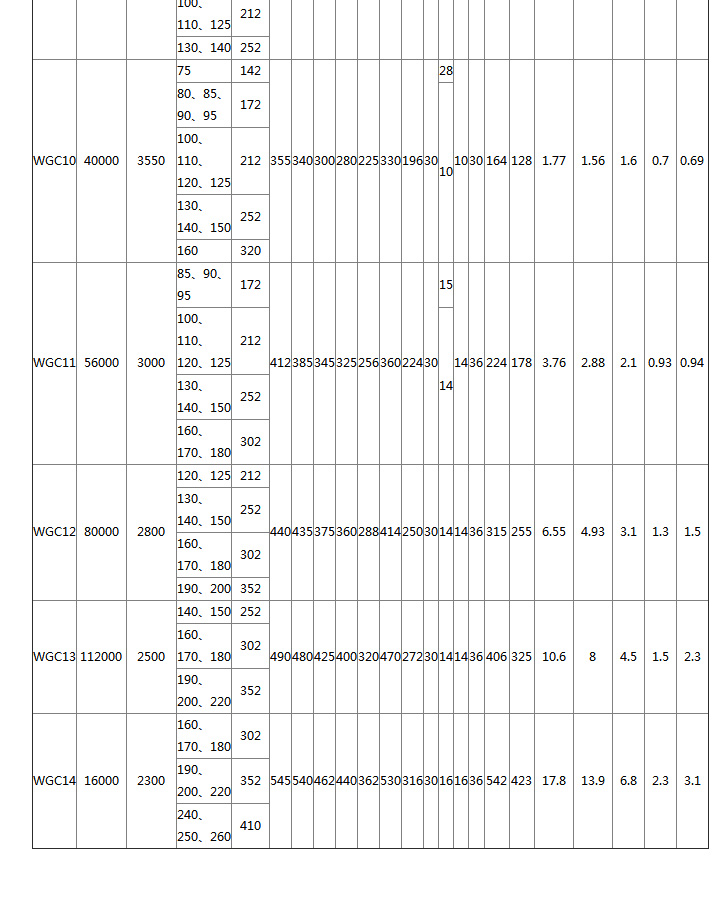

WGC vertical mounting drum gear coupling is used for the vertical shaft connection of the equipment. It is a kind of drum gear coupling. The difference is that the common drum coupling is used for lateral connection and the WGC vertical installation drum gear is connected. The shaft is longitudinally connected. In addition, the WGC vertical installation drum-shaped coupling is divided into two types: I type and II type. The type I is with a pressure cover type. The advantage is that the outer plate can be inspected and replaced by removing the pressure plate; The production process is complicated, the weight is high, and the price is high. The type II is not equipped with a gland type, and the advantage is that the price is cheap. WGC vertical mounting drum gear coupling allows for greater angular displacement relative to spur gear couplings, improves tooth contact conditions, improves torque transfer capability, and extends service life with angular displacement The contact state of the tooth width is composed of a ring gear having the same number of teeth and a flange half coupling with external teeth. When the WGC vertical installation drum-shaped gear coupling is in operation, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth periodically slide axially relative to each other, which inevitably forms tooth surface wear and power consumption. Therefore, the WGC is vertically mounted on the drum shape. The toothed coupling needs to work in a good and sealed condition. WGC vertical installation drum-shaped gear coupling has the same radial size and large bearing capacity as the gear coupling. It is often used for shaft transmission with low speed and heavy load conditions, high precision and dynamic balance gear coupling. The unit can be used for high speed transmission. WG type - basic type; WGP type - with brake disc type, suitable for matching with disc brakes; WGZ type - with brake wheel type, suitable for supporting with tile brakes; WGT type - connected to the middle sleeve type, suitable for two-axis long-distance connection, the allowable speed [n] depends on the length and quality of the intermediate sleeve, and the critical speed should be checked; WGC type - vertical installation type, used to connect vertical two-axis shaft drive; Type I--The sealed end cap is of separate type with large tooth spacing, which can allow large radial displacement and can be connected with Y, J1 and Z1 shaft extensions;     |

gear coupling

Tell:0511-85783292

Fax:0511-85019680(自動接收)

Mobile:18913433240

E-mail:1803877936@qq.com

Add:No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province Service

gear coupling

WGC Vertical Mounting Drum Coupling

WGC Vertical Mounting Drum Coupling

|

WGC vertical mounting drum gear coupling is used for the vertical shaft connection of the equipment. It is a kind of drum gear coupling. The difference is that the common drum coupling is used for lateral connection and the WGC vertical installation drum gear is connected. The shaft is longitudinally connected. In addition, the WGC vertical installation drum-shaped coupling is divided into two types: I type and II type. The type I is with a pressure cover type. The advantage is that the outer plate can be inspected and replaced by removing the pressure plate; The production process is complicated, the weight is high, and the price is high. The type II is not equipped with a gland type, and the advantage is that the price is cheap. WGC vertical mounting drum gear coupling allows for greater angular displacement relative to spur gear couplings, improves tooth contact conditions, improves torque transfer capability, and extends service life with angular displacement The contact state of the tooth width is composed of a ring gear having the same number of teeth and a flange half coupling with external teeth. When the WGC vertical installation drum-shaped gear coupling is in operation, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth periodically slide axially relative to each other, which inevitably forms tooth surface wear and power consumption. Therefore, the WGC is vertically mounted on the drum shape. The toothed coupling needs to work in a good and sealed condition. WGC vertical installation drum-shaped gear coupling has the same radial size and large bearing capacity as the gear coupling. It is often used for shaft transmission with low speed and heavy load conditions, high precision and dynamic balance gear coupling. The unit can be used for high speed transmission. WG type - basic type; WGP type - with brake disc type, suitable for matching with disc brakes; WGZ type - with brake wheel type, suitable for supporting with tile brakes; WGT type - connected to the middle sleeve type, suitable for two-axis long-distance connection, the allowable speed [n] depends on the length and quality of the intermediate sleeve, and the critical speed should be checked; WGC type - vertical installation type, used to connect vertical two-axis shaft drive; Type I--The sealed end cap is of separate type with large tooth spacing, which can allow large radial displacement and can be connected with Y, J1 and Z1 shaft extensions;     |

Zhenjiang Haicheng Machinery Manufacturing Co., Ltd.

? Haicheng Group All rights reserved.

???????????? Address: No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province

Service Hotline:18913433240

???????????? Company Tel: 0511-85783292 Company Fax:0511-85019680 (automatic

reception)

Copyright ? Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Copyright ? Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Add:No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province Service Tell:0511-85783292