|

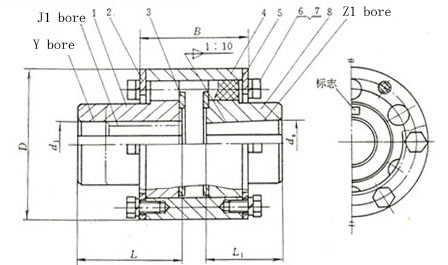

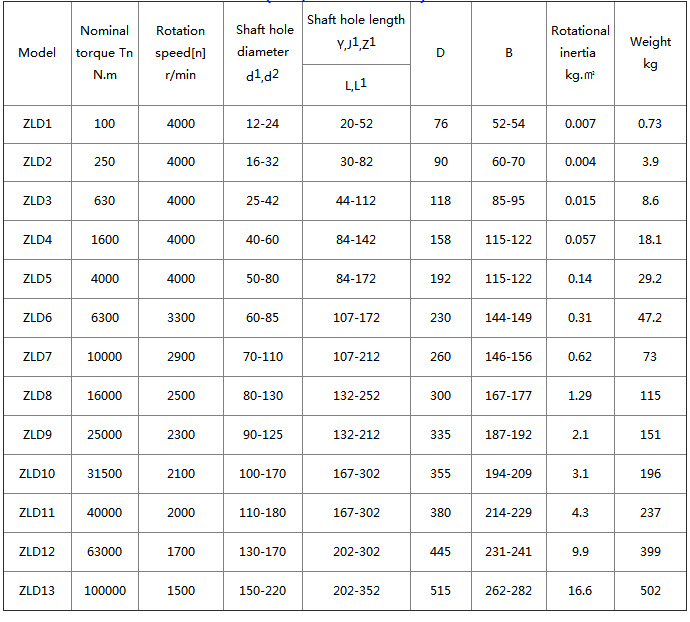

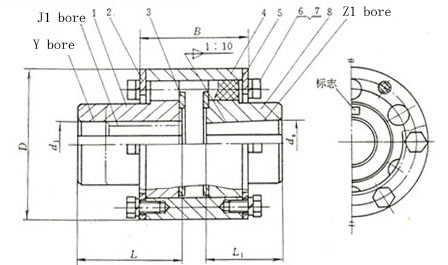

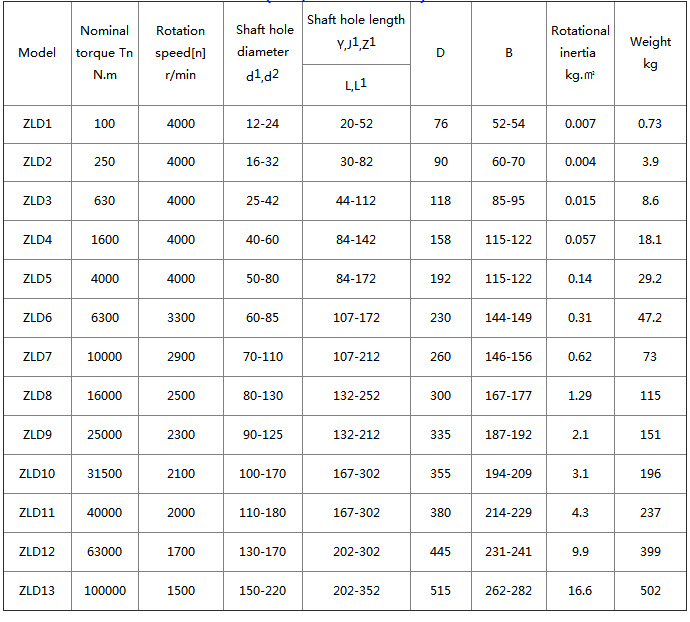

The elastic pin of the LZD type elastic pin gear coupling is turned by a nylon rod and placed in the matching hole between the two coupling halves and the outer sleeve, and transmitted through the elastic pin between the coupling and the outer sleeve. Moment, with a certain axis offset compensation and shock absorption performance. The pin can be removed and installed, and the baffle can be changed. The material is self-lubricating material and nylon is not required to be lubricated. Therefore, the LZD type elastic pin gear type coupling is easy to maintain, and has the advantages of small volume, light weight, simple structure, convenient replacement and low production cost compared with the toothed coupling. The LZD type elastic pin gear type coupling transmits a nominal torque of 100~100000N.m; the allowable speed is 4000~1500r/min; it belongs to the low speed high torque coupling. The LZD type elastic pin gear coupling is made according to the standard of GB/T5015-2003; the working temperature is -20~70°C; the axial compensation amount is ±1.5~3mm; the radial allowable compensation is 0.3~1.5mm; the angular tolerance is 0.5°. In addition, the biggest difference between the ZL (now LZ) type elastic pin gear coupling and the LZD type elastic pin gear coupling is that the LZD type pin gear coupling allows the shaft hole of one end of the coupling to be tapered. hole  . . |

flexible coupling

Tell:0511-85783292

Fax:0511-85019680(自動接收)

Mobile:18913433240

E-mail:1803877936@qq.com

Add:No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province Service

flexible coupling

LZD conical shaft hole elastic column pin gear coupling

LZD conical shaft hole elastic column pin gear coupling

|

The elastic pin of the LZD type elastic pin gear coupling is turned by a nylon rod and placed in the matching hole between the two coupling halves and the outer sleeve, and transmitted through the elastic pin between the coupling and the outer sleeve. Moment, with a certain axis offset compensation and shock absorption performance. The pin can be removed and installed, and the baffle can be changed. The material is self-lubricating material and nylon is not required to be lubricated. Therefore, the LZD type elastic pin gear type coupling is easy to maintain, and has the advantages of small volume, light weight, simple structure, convenient replacement and low production cost compared with the toothed coupling. The LZD type elastic pin gear type coupling transmits a nominal torque of 100~100000N.m; the allowable speed is 4000~1500r/min; it belongs to the low speed high torque coupling. The LZD type elastic pin gear coupling is made according to the standard of GB/T5015-2003; the working temperature is -20~70°C; the axial compensation amount is ±1.5~3mm; the radial allowable compensation is 0.3~1.5mm; the angular tolerance is 0.5°. In addition, the biggest difference between the ZL (now LZ) type elastic pin gear coupling and the LZD type elastic pin gear coupling is that the LZD type pin gear coupling allows the shaft hole of one end of the coupling to be tapered. hole  . . |

Zhenjiang Haicheng Machinery Manufacturing Co., Ltd.

? Haicheng Group All rights reserved.

???????????? Address: No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province

Service Hotline:18913433240

???????????? Company Tel: 0511-85783292 Company Fax:0511-85019680 (automatic

reception)

Copyright ? Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Copyright ? Zhenjiang Haicheng Machinery Manufacturing Co., Ltd. All Rights Reserved .

Add:No. 68, High-tech Development Zone, Zhenjiang City, Jiangsu Province Service Tell:0511-85783292